[TOC]

Use of RFID in the Logistics and Warehouse Sector

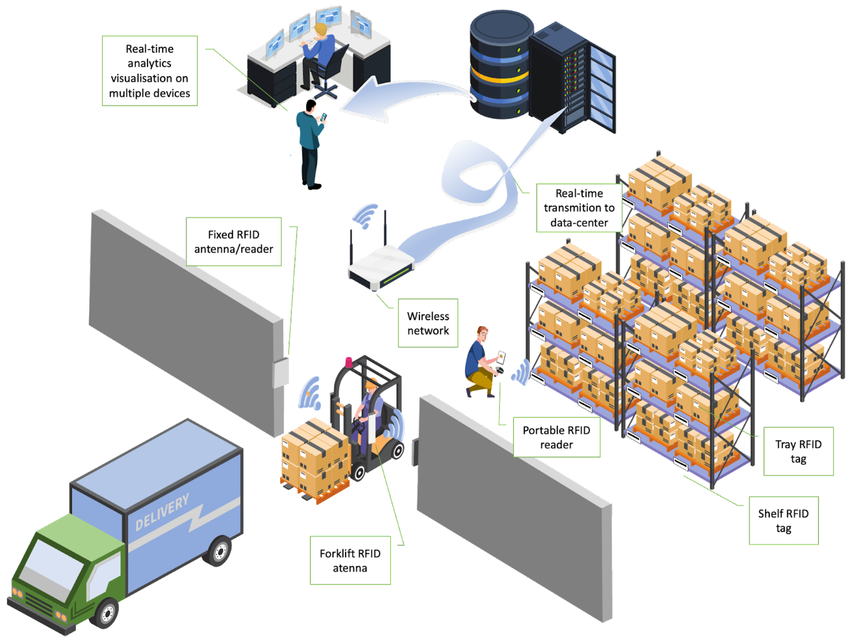

RFID (Radio Frequency Identification) technology is revolutionizing the way logistics and warehouse management are conducted, leading to a significant increase in operational efficiency and a reduction in costs. With the ability to automatically track goods and inventory in real-time, companies can gain a clearer and more accurate view of their operations, improving resource management and optimizing workflows.

RFID provides tangible benefits such as reducing shipping and receiving errors, better stock management, and quick product identification — critical elements in high-intensity logistics environments.

If you want to learn more about the basics of RFID technology, we invite you to visit our page dedicated to RFID technology, which offers a detailed explanation of how it works.

Importance of RFID in Logistics

The introduction of RFID technology in the logistics sector has marked a significant turning point in how companies manage the transportation, receiving, and storage of goods. This section examines the key benefits and transformations that RFID has brought to the industry.

Improved Operational Efficiency

RFID technology's ability to read and record information from multiple tags simultaneously, without the need for direct line of sight, dramatically reduces the time required for checking in and out products in the warehouse. This means fewer queues and delays, faster workflows, and an overall reduction in logistics processing time. Companies can manage larger volumes with the same amount of resources, increasing operational efficiency.

Cost Reduction

By using RFID, companies significantly reduce the risk of shipping errors, which can be costly in terms of both resources and reputation. Additionally, fewer inventory errors and more accurate available data allow for better planning and reduced need for excess stock, further lowering costs.

Improved Visibility

RFID adoption provides unprecedented visibility into the location and status of products within the supply chain. Logistics operators can track products from their arrival in the warehouse to final delivery, ensuring complete transparency that was difficult to achieve with traditional inventory management methods.

Decision Support

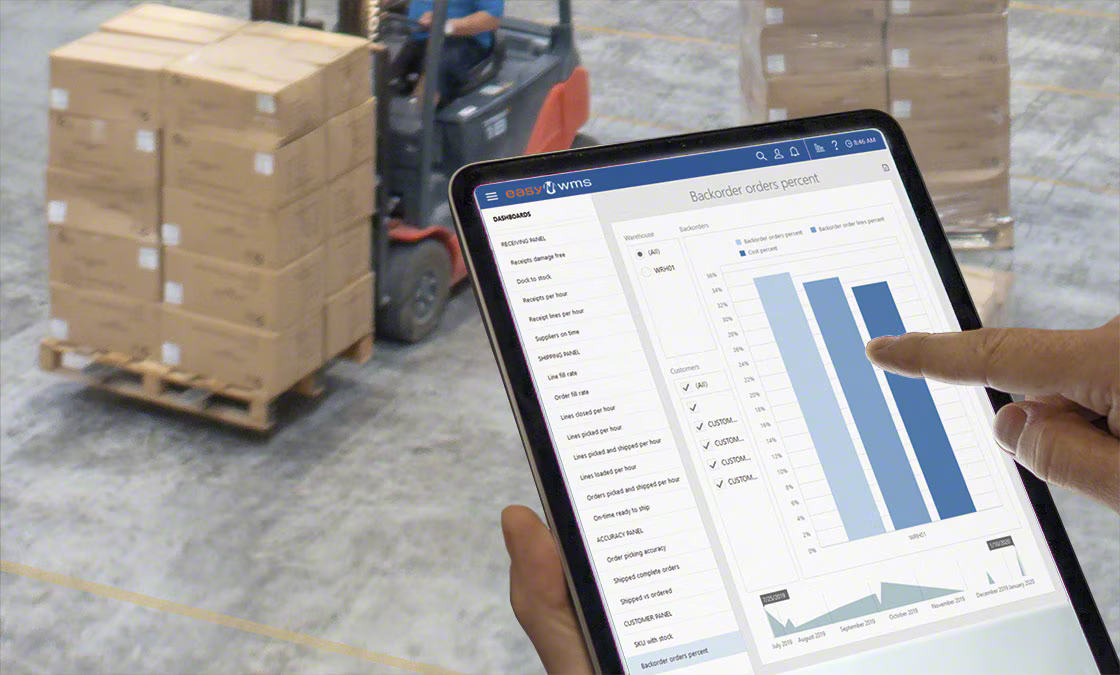

The data collected through RFID systems is extremely useful for analysis and reporting, allowing companies to make informed decisions based on accurate, up-to-date information. This leads to improvements not only operationally but also strategically, influencing decisions on purchases, production, and distribution based on concrete data rather than estimates.

Thus, RFID technology is not only improving daily operations in the logistics sector but is also redefining how companies plan and respond to market demands. Its impact is tangible and long-term, promising further innovations and improvements in warehouse and logistics practices.

Inventory Management with RFID

The adoption of RFID technology in inventory management has revolutionized warehouse operations, enabling far more efficient and accurate stock management. This section explores how RFID facilitates inventory processes, bringing significant benefits to companies in the sector.

Inventory Accuracy: One of the key benefits of RFID technology is improved accuracy in identifying and counting items. RFID tags can be read quickly and without manual errors, allowing real-time inventory updates. This greatly reduces inventory discrepancies and minimizes the need for costly periodic physical reconciliations.

Reduction in Inventory Time: With traditional systems, physical counting of items can be a long and laborious process. RFID, on the other hand, allows the simultaneous reading of hundreds of tags within seconds, drastically reducing the time spent on inventory. This frees up resources that can be deployed in other value-added activities, increasing overall warehouse efficiency.

Minimization of Errors and Theft: With improved traceability, RFID technology also helps reduce shipping and receiving errors and contributes to theft prevention. Every item with an RFID tag is tracked throughout the supply chain, reducing the chances of loss or unauthorized tampering.

Proactive Stock Management: Integrating RFID data with inventory management systems allows companies to move from a reactive to a proactive approach to stock management. Detailed, real-time information enables better demand forecasting and optimization of stock levels, avoiding both overproduction and inventory shortages.

Supply Chain Optimization: The improved visibility and accuracy of inventory data that RFID offers lead to overall supply chain optimization. This includes the ability to respond more quickly to market fluctuations, improving customer service and overall satisfaction.

Inventory management with RFID not only increases efficiency and reduces costs but also significantly enhances a company’s ability to adapt and respond to ever-changing market dynamics. By implementing this technology, the logistics and warehouse sector can realize substantial improvements in its daily operations.

Optimizing Shipping and Receiving Processes with RFID

The integration of RFID technology into shipping and receiving processes leads to a significant optimization of warehouse operations. This section describes how RFID enhances these critical aspects, reducing time and increasing reliability.

Speeding Up Loading and Unloading Processes

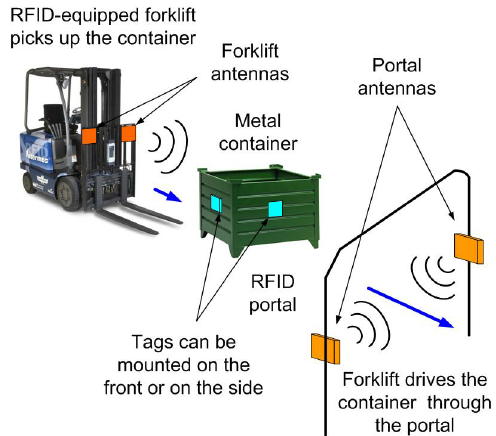

RFID allows for the quick and accurate reading of product tags during loading and unloading operations. This eliminates the need for manual barcode scanning, reducing the time required to process inbound and outbound shipments. This efficiency translates into fewer bottlenecks and faster warehouse operations, allowing for the handling of higher volumes of goods.

Improvement in Shipping Accuracy

With RFID, every item can be individually tracked, ensuring that orders are complete and accurate. This minimizes shipping errors, such as missing items or sending the wrong products, which can be costly and damage the company’s reputation. The ability to automatically verify orders against invoices and shipping documents further enhances accuracy.

Increased Traceability

RFID technology provides unprecedented visibility into where products are located along the supply chain. This level of traceability not only helps monitor items in transit but also improves the management of returns and warranties. The ability to track products in real-time also enhances security by reducing the risk of loss or theft during transport.

Integration with Warehouse Management Systems

RFID can be easily integrated with existing warehouse management systems, automating the recording of stock entries and exits. This syncs inventory data with actual shipping and receiving activities, providing a consistent and accurate view of warehouse status. Such integration also enables further automated decision-making processes, such as automatic reordering and optimal resource allocation.

Reduction in Operating Costs

By decreasing the time required for shipping and receiving operations and reducing errors, RFID contributes to a substantial reduction in operating costs. Less time spent handling and correcting errors means more resources available for other value-added activities, increasing overall business efficiency.

Optimizing shipping and receiving processes with RFID technology not only increases productivity but also enhances customer satisfaction by ensuring that the right products are delivered on time and in perfect condition. This represents a significant competitive advantage in an increasingly demanding market.

RFID Integration with Other Technological Systems

RFID technology does not operate in isolation; its integration with other management systems and IT technologies is essential to amplify its benefits. This section describes how RFID integrates with various systems to improve the efficiency and effectiveness of logistics operations.

RFID Integration with ERP Systems (Enterprise Resource Planning)

RFID can be directly linked to ERP systems for automatic, real-time updates of stock and operations. This integration allows for more accurate and timely resource management, improving the planning and execution of logistics activities. Data collected by RFID feeds into the ERP system with precise information, helping companies make more informed decisions regarding production, distribution, and replenishment.

Collaboration with Warehouse Management Systems

Integrating RFID with warehouse management systems optimizes product location tracking within warehouses. This allows for faster and more accurate retrieval of items, reducing wait times and improving customer service. Additionally, the automated management of inventory data reduces errors and increases warehouse operation efficiency.

Synergy with Automation Technologies

Using RFID together with automation technologies such as automated transport systems and picking robots significantly improves the speed and accuracy of warehouse operations. RFID provides automated systems with the necessary information to efficiently locate and handle products, facilitating faster operations with less human intervention.

Enhancing Customer Experience

By integrating RFID with CRM (Customer Relationship Management) systems and other customer interaction platforms, companies can offer more personalized and responsive experiences. For example, improved traceability allows customers to be informed in real-time about the status of their shipments, increasing transparency and trust.

The Future of RFID in Logistics

As RFID technology continues to mature, its impact on the logistics sector is set to grow, driven by technological innovations and increased adoption. This section discusses some of the emerging trends and potential future developments that could further enhance the effectiveness of RFID in logistics.

RFID and IoT Integration (Internet of Things)

One of the most promising trends is RFID integration with IoT. This convergence will enable RFID devices to communicate not only with centralized systems but also with each other, creating a network of interconnected devices that can exchange real-time data, increasing operational efficiency and providing new metrics for data analysis.

Improvements in RFID Tag Technology

Advances in RFID tag technology could lead to smaller, cheaper tags with greater memory capacity and longer battery life. This will make RFID applicable to an even wider range of products and scenarios, including those that currently do not support the cost or size of existing tags.

RFID and Artificial Intelligence

The integration of RFID with artificial intelligence (AI) offers significant potential for advanced automation. AI can use data collected from RFID systems to improve real-time routing decisions, autonomously manage stock, and predict problems before they occur, thus enhancing efficiency and reducing operational costs.

Sustainability and RFID

As sustainability becomes an increasingly important criterion for businesses across all sectors, RFID can play a crucial role in supporting more sustainable business practices. By accurately monitoring resource use and optimizing supply chains, RFID can help reduce waste, improve energy efficiency, and minimize the environmental impact of logistics operations.

Increased Emphasis on Data Security

As the use of data collected from RFID increases, there will be a greater need to protect this data against unauthorized access and security breaches. We can therefore expect a strengthening of security measures and protocols to ensure the privacy and protection of sensitive data.

The future of RFID technology in the logistics sector looks bright and full of potential. Expected developments will not only expand its practical applications but also contribute to making logistics operations more efficient, sustainable, and secure.

Conclusions

RFID technology is revolutionizing the logistics and warehouse sector, offering solutions that significantly improve operational efficiency, reduce costs, and increase security and traceability. From precise inventory management to speeding up shipping and receiving processes, RFID adoption allows companies to optimize every stage of their logistics operations.

With real-time inventory management, companies can reduce errors and minimize discrepancies, ensuring that stock levels are always accurate. The optimization of shipping and receiving processes enabled by RFID not only speeds up operations but also reduces operational costs, improving customer satisfaction with faster and more accurate deliveries.

Improved warehouse security and traceability ensure that assets are constantly monitored, preventing losses and thefts, and ensuring regulatory compliance. Additionally, integrating RFID technology with other technological systems, such as ERP and warehouse management systems, creates a connected and highly efficient ecosystem that supports informed and strategic operational decisions.

Looking to the future, RFID technology will continue to evolve, with innovations that will make tags smaller, cheaper, and more powerful. The growing integration with the Internet of Things (IoT) and the development of smarter and more sustainable RFID systems will offer new opportunities to further optimize logistics operations.

In summary, RFID represents a milestone in improving logistics and warehouse operations. Companies that adopt this technology can expect a positive transformation in their operations, achieving greater efficiency, security, and competitiveness in an increasingly dynamic market. RFID implementation is not just a technological choice but a crucial business strategy for future success.